Nano Glass, also known as Nano Crystallized Glass Stone, is a nanoporous marmoglass and artificial white stone that has been crystallized without pores. It has a specular gloss over 95 degrees and is non-porous, so liquids and oils cannot pass through it. As a result, nano glass is a very strong and glossy engineered stone that can be used for countertops, flooring, and wall cladding for both interior and exterior applications.

The main raw material of Nano glass stones are SiO2, Nano glass is manufactured from a blend of natural materials that is 75 percent silica and 25 percent other natural minerals. The mixture is poured into a mold to form either a slab or a tile, and it is heated to a temperature ranging from 1,550 degrees Celsius to 1,800 degrees Celsius. For 24 to 26 hours, This is a process similar to how lava develops in a volcano when it starts to cool down.

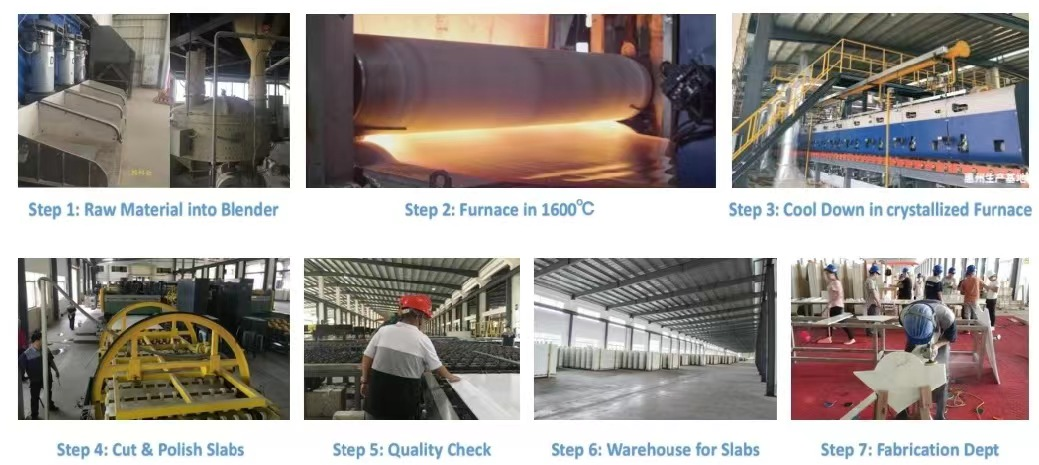

Six Steps to Producing nano glass slab

- Step 1: Raw material into blender

- Step 3: Cool down in crystallized furnace

- Step 5: Quality Check

- Step 2: Furnace in 1600 ℃

- Step 4: Cut and polish slab

- Step 6: Warehouse for slabs

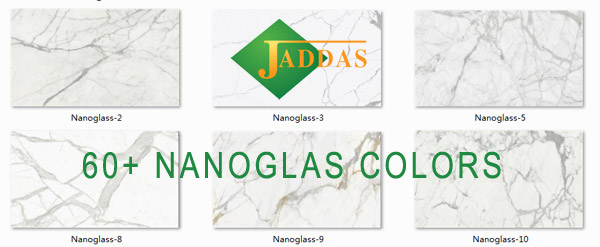

How many colors and style of nano glass?

In 2020, our company introduced 3D printing technology to print the designed colors on the nano glass surface, 3D Inject Printing Nano glass is marble look Nano glass base on Pure White Nano glass by 3D Printing Technology. Various kinds of Natural white Marble Patterns can be made as preferences, now more than 60 colors have been developed to choose from, and color customization services are also accepted.

Such as Pure White Nano Glass slab, Calacatta Nano Glass, Carrara White Nano Glass Stone, full body Wood Vein Nano Glass Stone, White / Grey / Beige Thin Nanoglass slabs etc.

Features of Nano Glass Stone

- Unique in superior whiteness, brilliant radiance and no chromaticism Perfect snow-white stone, Over 95 degree super glossy but gentle to the eye.

- Zero water absorption, good in acid & alkaline resistance, high temperature, chemical and stain resistance and can be re-polished.

- Green environment, no toxin and no radiation, able to be in direct contact with food.

- Anti-bending, anti-pressure, anti-impact, perfect for kitchen countertops, dinner table tops.

- White color stone is the most popular and classic in the world and never be out, and you will get the prefect decoration by the crystallized glass panel.

- Enjoy excellent processing of various edge finishing with automatic bridge cutting machine, hand cutting machine or portable cutting machine to cut and drill holes like natural stone.

Nano Glass Stone Application:

- Interior & external wall cladding

- Flooring Tile, Stair, Column cladding

- Basin, Countertops, bench tops, work tops, table tops, Bar tops etc.

- Bath, Kitchen, any tops, round pillar and furniture decoration, etc.

Marmoglass Inc – Nano Glass Stone Manufacturer

Marmoglass Inc is Nano Glass Slabs Professional Manufacturer since 2012 from China.